Santex is the only company in Italy to produce traditional and surgical dressing. In our modern clean room, we follow the entire production and packaging cycle of a wide range of medical devices.

Santex has a factory in Sarego (Vicenza province). Here, thanks to qualified staff, technical-instrumental resources, and modern production systems, it guarantees constant control over the entire manufacturing process for dressing devices.

Since 1961, Ortavatt, Alfaplast, Ortoplast, and Ortobend have accompanied the work of sector operators in hospitals and healthcare facilities throughout Italy.

Santex has always believed and invested in a national production logic, certain that, for such delicate devices as those for dressing, there is no better guarantee of safety than the quality of the origin, which continues to be Sarego factory.

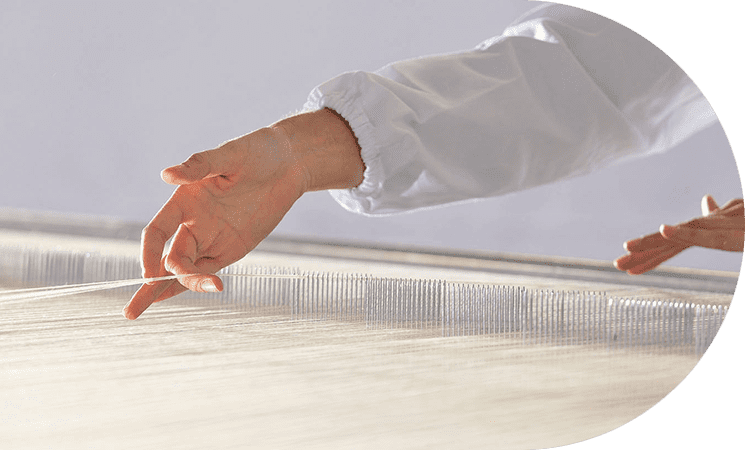

There, as in the past, the numerous looms begin the work of transforming the yarn. After the warping and dressing departments have made it suitable for fabric construction, and subsequently – after having passed the bleaching and drying phase – it is sent to the white room for the definitive diversification into a multiplicity of finished devices ready for use.

In the modern company’s clean-room, all the traditional cotton gauze dressing items are packaged, which can be used from simple ward use to delicate use in the operating room, where sterile devices in various packages usually have access.

The range of the main dressing products offered by Santex is vast: cotton wool, gauze pads, and rolls, cut bandages, Orlobend hemmed bandages, Retesan elastic net, stretch gauze tablets, Foldready bent gauze tablets, laparotomy gauze, swabs for surgical use, bandages and gauze tampons medicated with iodoform.

A specific department is then designed for the production of orthopedic material. Here are produced materials for brands with which the operators in the sector have always been familiar: the Ortovatt orthopedic wadding, the Ortomaglia tubular knit gauze, the Alfaplast, Ortoplast, and Ortobend plaster bandages.

Santex guarantees a level of microbial contamination on its products, before sterilization, always lower than 100 U.F.C./g, that is lower than one-fifth of the level required for non-sterile devices. Packaging and sterilization are the most important phases of the production process and take place in the white room where, thanks to continuous checks and strict internal regulations such as limited access, constant thermo-hygrometric control, absolute filtering of the recirculated air, cleaning wet and dry of the parts in contact with the devices, a very high level of hygiene is maintained, which allows rapid and effective sterilization of the devices and guarantees maximum safety.

Santex uses a series of processes validated according to current regulations for saturated steam sterilization.

Our values not only concern devices but also our attention to the environment.

Thanks to our 2MW cogenerator we self-produce electrical and thermal energy by reusing 80% of that employed.

Through rigorous steam sterilization, our products are sterilized by using steam to avoid creating risks for the environment or people.

Finally, we have abolished the use of gas with ethylene oxide (EtO): this sterilization process is considered carcinogenic and banned in many countries such as the USA.

19/10/2020

19/10/2020

Even in a period of emergency like this, Santex co...

Read more 03/07/2020

03/07/2020

As the number of incontinence sufferers increases,...

Read more 03/07/2020

03/07/2020

The Quality laboratory at the Santex plant checks ...

Read more 03/07/2020

03/07/2020

The warehouse, first inaugurated in June 2018, is ...

Read more